Well-designed Alc Panel Production Line - PVC Laminated Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Well-designed Alc Panel Production Line - PVC Laminated Production Line – Amulite Detail:

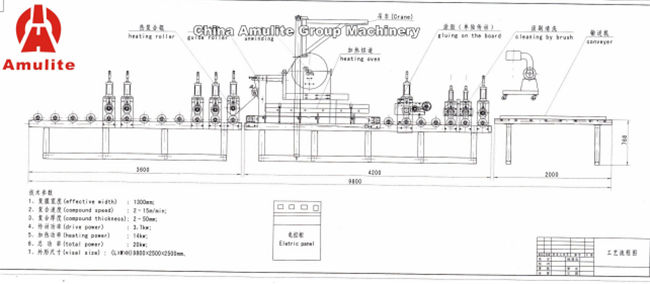

1.AM1300 Type Laminating Machine For Gypsum Boards

(it is used to wrapping PVC film on the surface of gypsum boards)

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 14kw |

| driver power | 3.7kw |

| total power | 20kw |

| visual size(L*W*H) | 9800*2500*2500mm |

flow chart of AM1300

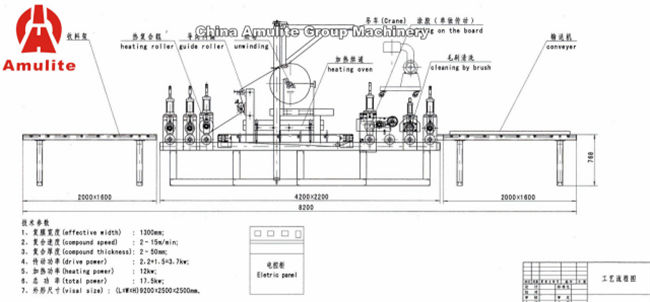

2.AM1300 Type Laminating Machine

(It is used to wrapping aluminum foil on the back of gypsum board.)

Technical parameter of AM1300

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 12kw |

| driver power | 2.2kw |

| total power | 17.5kw |

| visual size(L*W*H) | 9200*2500*2500mm |

Flow chart of AM1300

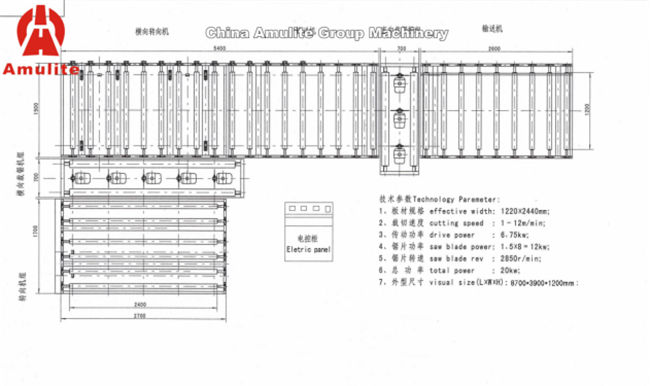

3. AM1220*2440 Type Cutting Machine for Gypsum boards

Technical parameter of cutting machine

| Effective sizes of board | 1220*2440mm |

| Min cutting sizes | 500*500mm |

| cutting speed | 2—12m/min |

| driver power | 6.75kw |

| Saw blade quantity | 8pcs |

| Saw blade power | 1.5kw*8=12kw |

| Saw blade REV. | 2850r/min |

| Power of brush cleaning | 7kw |

| total power | 27kw |

| visual size(L*W*H) | 8700*5300*1200mm |

Flow chart of AM1220*2440

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for Well-designed Alc Panel Production Line - PVC Laminated Production Line – Amulite, The product will supply to all over the world, such as: Wellington, kazan, Indonesia, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.