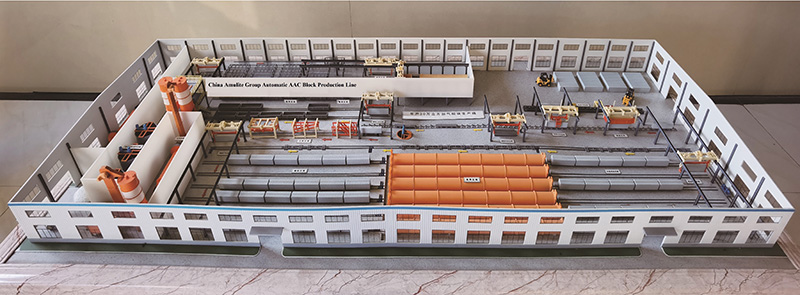

Amulite Automatic AAC Block Production Line

Short Description:

Product Detail

Product Tags

What Is AAC Block?

The Concept Of AAC Block:AAC Block Is Based On Siliceous Materials(Sand,Fly Ash,Silica-Containing Materials Etc),And Calcareous Materials(Lime,Cement) As The Main Raw Materials,Mixed With Air-Entraining Agents(Aluminum Powder),After The Process Raw Materials Batching,Slurry Mixing,Pouring,Pre-Curing,Cutting,Autoclave ,Curing Process And Package To Produce Out AAC Blocks Finished Products;It Is Called Aerated Concrete Because It Contains A Large Number Of Uniform And Small Pores After It Is Aerated.

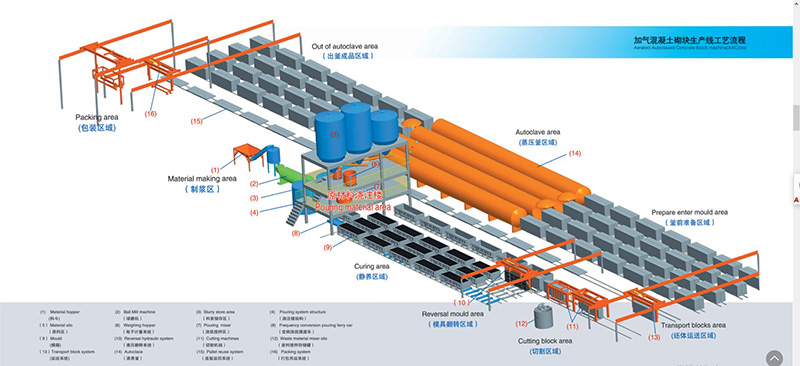

What Is The Process To Produce AAC Block Products?

What Is The Process To Produce AAC Block Products?

1) :All Raw Materials Metering And Mixed Slurry;

2) :Slurry Enter Into Pouring System,After Mixing Then Pouring Into Mold Box;

3) :Inside Mold Box(Panel Reinforcement),After A Certain Temperature And Pre-Curing Time;

4) :After The Wet Panel Reaches A Certain Hardness,The Mold Box And Panels Will Be Hoisted To The Cutting Machine By The Turnover Crane,And The Turnover Crane Completes The Following Function:

5) : A :Is To Turn The Mold Box 90 Degree In The Air,(One Side Of The Mold Box Becomes The Support Trolley Plate For The Wet Panel Body Until Autoclave Process Finished),

6) :B :Is To Hoist To The Trolley Or The Cutting Support Frame To Completely Open The Mold;C:The Took Off Mold Frame And The Return Autoclave Side Plate Are Recombined To Form A Mold Box After Cleaning,Spray Oil And Re-Pouring ;

7) :And The Wet Panel Body Is Cut In Six Steps On The Cutting Machine: 1:First Cuts Both Sides Of The Panel Body Vertically;2:Then Cuts Longitudinally And Horizontally;

8) :Finally Cuts Horizontally Horizontal Or Knife Cutting;

9) :The Cut Panel Body Is Hoisted From The Semi-Finished Product Crane Together With The Bottom Plate To The Autoclave Trolley;

10) :Then Grouped Into The Autoclave For High Temperature And High Pressure Curing;

11) :After Well Autoclave Curing,The Trolley Will Be Took Out And Leave The Autoclave ;

12) :The Finished Products Are Stacked Or Loaded On The Truck By The Finished Product Hosting Crane,Packaged Well;

13) :The Autoclave Curing Side Plate Are Returned ;

About Main Raw Materials Introduction

The Production Of AAC Block Is Rich In Raw Materials,Especially The Use Of Fly Ash As The Raw Materials Which Can Not Only Comprehensively Use Industrial Waste Residues,Treat Environmental Pollution,And Not Damage Farmland,But Also Create Good Social And Economic Benefits,It Is A Good Substitute For Traditional Solid Clay Bricks.Good Promising Wall Products Have Been Strongly Welcomed By Government,Estate Company,Construction Team,And Government Has Made Tax Policy ,Environmental Protection Policy Support,We Can Foreseen Broad Market Development Prospects;

1. Fly Ash/Quartz Sand

Fly Ash/Quartz Sand Is The Main Core Raw Materials Of AAC Block Product,And Is The Main Source Of The Silicon And Aluminum Components Of Aerated Concrete;

2. Cement

Cement Is The Main Source Of The Strength Of AAC Block,It Provides The Main Calcareous Materials For AAC Block,Cement Suitable For The Production Of AAC Block Should Be Selected Mainly In Terms Of Type And Grade Of Cement;In Production,52.5 Grade Ordinary Portland Cement Should Be Selected First .In General,In Order To Reduce Production Cost,42.5 Grade Ordinary Portland Cement Can Be Used Also ;

3. Lime

Lime Is Also One Of The Main Raw Materials For The Production Of AAC Blocks.Its Main Function Is To Cooperate With Cement To Provide Effective Calcium Oxide,So That It Can Interact With SIO2 And Al203 In Siliceous Materials Under Hydrothermal Conditions To Produce Silicon Hydrate Calcium Acid.Therefore,Lime Is One Of The Main Strength Sources Of AAC Block.The Effective Calcium Oxide Content Of Lime Used To Produce AAC Block Should Be Higher Than 65%,Preferably Higher Than 80%.

4. Gypsum

Gypsum Is A Regulator Of The Air Evolution Process In AAC Block Production.The Regulating Effect Of Gypsum Is Mainly Reflected In The Delay Of Quicklime Digestion And Slurry Thickening Speed.The Main Chemical Component Of Gypsum Is CASO4;There Are Three Types Of Gypsum On The Market;Raw Gypsum,Anhydrite And Plaster Of Paris.In Addition,Waste Gypsum Is Also Produced In The Chemical Production Process.Such As Phosphogypsum From The Production Of Phosphate Fertilizers,Fluorogypsum From The Production Of Fluorine Chemicals,And Gypsum From The Production Of Titanium Dioxide.These Gypsum Are Low In Cost And Can Replace Natural Gypsum And Reduce Production Costs;

5. Air Generating Agent

AAC Block Must Have A Air-Generating Agent To Create Pores In The Block To Form A Lightweight Porous Structure;

6. Foam Stabilizer

After The Air Generating Agent Gasses,Due To The Thin Form Wall,It Is Easy To Break And Destroy The Foam Under The Interference Of Various Conditions,Which Affects The Quality Of The Concrete.Therefore,It Is Necessary To Add A Foam Stabilizer To The Slurry.

Production Process

1) :Storage And Supply Of Raw Materials For AAC Block

Raw Materials Are Transported Into The Factory By Automobiles,And Fly(Sand,Stone Powder) Is Concentrated In The Raw Materials Yard,And When Used,It Is Conveyed Into The Hopper.Bagged Cement Or Bulk Cement Is Stored In The Cement Warehouse.When In Use,It Is Loaded And Transported Into The Hopper.Chemicals,Aluminum Powder Etc Are Placed In The Chemical Storage And Aluminum Powder Storage,Respectively,And Convey To The Production Workshop When Used.

2) ![]() rocessing Of Raw Materials For AAC Blocks

rocessing Of Raw Materials For AAC Blocks

Fly Ash(Or Sand,Stone Powder) Is Sent To The Ball Mill Through Electromagnetic Vibrating Feeder And Belt Conveyor,And The Ground Fly Ash(Or Sand,Stone Powder) Is Sent To The Slurry Tank For Storage By The Fly Ash Pump.

The Lime Is Sent To The Jaw Crusher By The Electromagnetic Vibrating Feeder And The Belt Conveyor For Crushing.The Crushed Lime Is Conveyed To Lime Storage Tank By The Bucket Elevator,And Then Sent To The Ball Mill By The Screw Conveyor.The Screw Conveyor And Bucket Elevator Are Fed Into The Powder Batching Tank.After The Chemicals Are Manually Measured In A Certain Proportion,A Solution Of A Certain Concentration Is Made And Sent To The Storage Tank For Storage.

The Aluminum Powder Is Conveyed From The Aluminum Powder Warehouse To The Production Workshop,And Is Lifted To The Second Floor Of The Batching Building With An Electric Hoist.Pour Into The Mixer To Add Water Quantitatively,And Stir It Into An Aluminum Powder Suspension.

3) :Slurry Mixing,And Pouring Of AAC Blocks;

Lime And Cement Are Sequentially Sent To The Automatic Weighing Scale By The Screw Conveyor Under The Powder Batching Tank For Cumulative Measurement.There Is A Screw Conveyor Under The Scale To Evenly Add The Materials Into The Pouring Mixer.

Fly Ash(Or Sand,Stone Powder) And Waste Slurry Are Put Into The Measuring Cylinder For Measurement.After Various Materials Are Measured,The Mold Is In Place,And The Slurry Can Be Stirred.The Slurry Should Meet The Process Requirements(Approximately 45℃) Before Pouring.If The Temperature Is Not Enough,Autoclave Heating Can Be Carried Out In The Slurry Metering Tank,And The Aluminum Powder Suspension Can Be Added 0.5-1 Minute Before The Materials Poured;

4) :AAC Block Pre-Curing And Cutting

After Pouring,The Mold Box Is Pushed Into The Initial Curing Room By A Conveyor Chain For Gasification And Initial Setting.The Room Temperature Is 50~70℃,And The Initial Curing Time Is 1.5-2Hours(According To The Favorable Geographical Conditions,This Process Can Be Eliminated).Use A Negative Pressure Hoist To Hoist The Mold Frame And The Wet Block Body Onto The Cutting Table Where The Bottom Plate Of The Autoclave Trolley Is Placed In Advance.Take Off The Mold Frame.The Cutting Machine Cross-Cuts,Longitudinally Cuts,And Mills The Wet Block. The Mold Frame Is Hoisted Back To The Mold Truck For Clean And Degreasing,And Then Lifted To The Mold Truck For The Next Casting.The Cut Block Body And The Bottom Plate Of The Autoclave Are Hoisted On The Autoclave Trolley With A Crane And Placed On Two Floors.There Are Four Supports Between The Floors,And Several Autoclave Trolley Are Grouped Together.

The Waste Materials At The Edges And Corners Of The Wet Block Body Produced During Cutting Is Sent To The Waste Slurry Agitator Next To The Cutting Machine By A Screw Conveyor,And Water Is Added To Make A Waste Slurry For Use In Batching.

5) :Autoclaved AAC Block And Finished Product.

After The Body Is Assembled On The Parking Line In Front Of The Autoclave,Open The Autoclave Door That Is Going Out Of The Autoclave,First Pull Out The Finished Autoclave Trolley In The Autoclave With A Hoist,And Then Pull The Autoclave Trolley To Be Autoclaved Into The Autoclave With A Hoist The Autoclave Is Maintained.The Finished Products On The Autoclave Trolley Are Hoisted To The Finished Product Warehouse By A Bridge Crane,And Then Transported To The Finished Products Yard By A Forklift Truck.The Empty Autoclave Trolley And The Bottom Plate Of The Autoclave Running Are Hoisted Back To The Carriage Return Line,And The Stacker Is Pulled Back By A Hoist After Cleaning.Go To The Next Cycle.

Production Equipment Show

1):Material Grinding And Making Slurry Section

| The Traditional Process Of Slurry Density Control Is Not Strict .The Density Of Protoplasm Is Often Through Artificial Measurement .The Error Is Bigger .The Density Of Circulating Plasma Basic Is Used To Control Based On Experience .So In The Production Of High Quality Low Volume Products .Qualified Rate And Product Quality Are Not Ideal .The Density Of Amulite Using The Latest Pipeline Measurement Method Has The Following Advantages1.The Slurry Is Circulated Between The Tank And The Densimeter, The Slurry Density Data Is Measured By Density Pipeline In Real Lime And Feedback To The Central Control Room .In Order To Adjust The Water Ratio Of The Pulping Of The Ball Mill And The Filling Of The Slurry Tank .The Purpose Of Continuous Correction Of Real-Time Density Is Achieved:2.The Density Pipe Shall Measure The Concentration Of All The Slurry .Measure The Accuracy Without Error .And Then Flush The Entire Pipe After The Shift To Ensure The Accuracy Of The Next Measurement. |  |

|||

|

||||

| Fly Ash Slurry Making Machine | Slurry Storage Mixer | Material Scale | Pouring System | |

|

2):Turnover And Cutting Section |

||||

Main Features Of Amulite Cutting Machine 1) :Simple-Structured ,Convenient To Install And Maintain;2) :Fixed To The Ground,Driven By Planet-Gear Reducer,While Doing Vertical Cutting,The Cutting Machine Does Eccentric And Swinging Cutting Which Increases Cutting Efficiency.Makes It More Convenient To Change Cutting Size. Main Features Of Amulite Cutting Machine 1) :Simple-Structured ,Convenient To Install And Maintain;2) :Fixed To The Ground,Driven By Planet-Gear Reducer,While Doing Vertical Cutting,The Cutting Machine Does Eccentric And Swinging Cutting Which Increases Cutting Efficiency.Makes It More Convenient To Change Cutting Size.

3) :Absorbing German Technology,Added Vacuum Aspirator,This Cutting Machine Can Get Rid Of Waste Materials Above Easily Without Destroying Any Part Of Finished Blocks And Assures Products Pass Rate; 4) :With 6-Side Cutting Of The Whole Block,Product Pass Rate Is Increased Because The Quality Of Finished Products Will Not Be Affected By The Change Of Moulds Any More. 5) :High Roughness Of The Surface Of Finished Blocks Is Favorable For Building Operation And Construction. 6) :Adopting Positioning Numerical Control Technology,This Machine Reduces Shaking In The Process Of Turning,Moving,Cutting And Transporting.Furthermore,It Can Be Upgraded To PLC Control System At The Request Of The Client So As To Increase Product Pass Rate. |

||||

|

||||

|

Hydraulic Frequency Convert Turnover Crane |

Horizontal Cutting Machine |

|||

| 1) :Hydraulic Frequency Convert Turnover Crane Turns The Mold Box With Block In 90 Degree Turnover,Put It On The Frequency Convert Block Dragging Trolley And Process Demold Works;2) :Frequency Convert Block Dragging Trolley Drags The Block To Cutting Machine To Be Cut.Turnover Crane Reorganizes,Cleans And Polishes Mold Box And Pallets To Prepare Them To Be Reused. | Turnover Crane Turns The Mold 90 Degree,Demold And Puts The Whole Block And Bottom Plate Onto Block Dragging Trolley.The Block Dragging Trolley Will Take The Whole Block Into Cutting Machine,And Finish Horizontal Cutting,Peeling The Whole Block By Two Sides,And Separating Wasted Materials. | |||

|

||||

|

3):Turnover Crane To Remove The Bottom Waste Material |

||||||||||

|

This Device Is Self-Developed By Amulite Group To Help Our Customers Completely Solving The Bottom Materials Waste Problem.This Device Includes Turnover Platform And Crane,It Can Remove The Top And Bottom Waste Material.This Crane Also Can Be As The Semi-Product Transport Crane. |

|||||||||

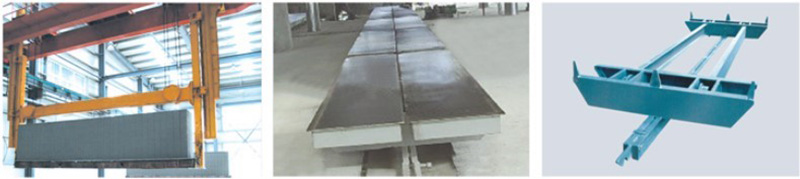

| Transport Crane Before Autoclave | Base Plate | Autoclave Trolley | ||||||||

|

||||||||||

| After Cutting,Transport Crane Carry Block To Autoclave Trolley For Enter Autoclave.This Device Has Simple Structure,Stable Operation,Good Quality And Easy To Maintain. | The Base Plate Designed By Amulite Group Can Also Be Side Plate,No Need To Change Until Come Out Of Autoclave.It Is Made By The Manganese Steel And Never Deformation Under High Temperature And Pressure. | It Is Composed Of Good Quality Profile Steel And Has Simple Structure .Stuck And Distortion Will Not Happen In The High Temperature And High Pressure Autocalve Curing Environment In Autocalve.The Crane Put The Wet Block On The Autocalve Curing Trolley And Into The Autoclave To Be Autoclave Conserved Until Removing The Finished Blocks; | ||||||||

|

4):Finished Product Handling Equipment |

||||||||||

|

Usually The Autoclaved Blocks And Plates Will Have Adhesions Sometimes.The Seperating Machine Is To Complete Separate The Adhesion’s Blocks Without Any Damage To The Blocks,Which Integrate The Function Of The Traditional Separating Machine And The Finished Product Carrier.Each Separating Hand Is Controlled Independently,Solved The Problem Of Separating The Blocks And Panels On The Same Mold;The Equipment Realizes An Efficient And Gentle Processing,Lowering The Overall Cost And Ensuring The Quality Rate At The Same Time. | |||||||||

|

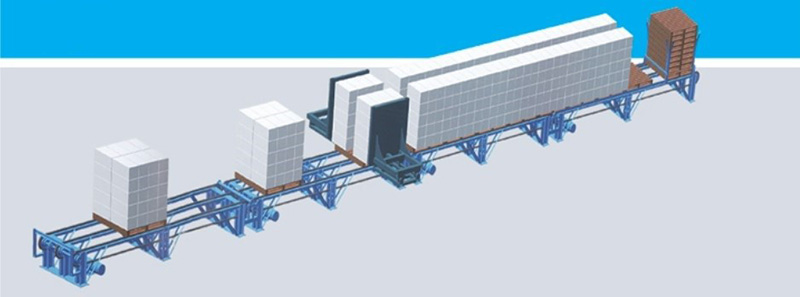

Convey And Package Line |

||||||||||

|

||||||||||

| This System Line Includes Conveying And Packing Line For Wooden Pallets Which Is Mainly Designed For The Finished AAC Blocks.The Whole Mold Products Will Be Moved Onto The Wooden Pallet At One Time By Means Of Clamping Device For Finished Products For Further Convey Distributing And Packing On This Line.This Machine Has Such Characteristics As Automatic Distribution By The Control Of Computer ,Precise Positioning During Convey And Automatic Separation Of Loaded Wooden Pallet In Which Case It Is Convenient For Packing And Shipment. | ||||||||||

|

5):More Machines Show |

||||||||||

Finished Products Clamp Finished Products Clamp |

Rotary Clamp Rotary Clamp |

|||||||||

|

||||||||||

| Special Crane For Panels | Plug Machine | Open Slot Machine | ||||||||

|

||||||||||

| Ball Mill | Jaw Crusher | Autoclave | Boiler | |||||||

|

||||||||||