Europe style for China One-Step Laminated Film PVC Lvt Vinyl Flooring Production Line

Short Description:

It is used to wrapping PVC film on the surface of gypsum boards.

Product Detail

Product Tags

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Europe style for China One-Step Laminated Film PVC Lvt Vinyl Flooring Production Line, We warmly welcome good friends from all walks of life to cooperate with us.

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for China PVC Floor Sheet Machine, Rigid PVC Floor Sheet Production Line, With the development and enlargement of mass clients abroad, now we’ve set up cooperative relationships with many major brands. We’ve got our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We’re provideing high-quality, low-cost products and solutions and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

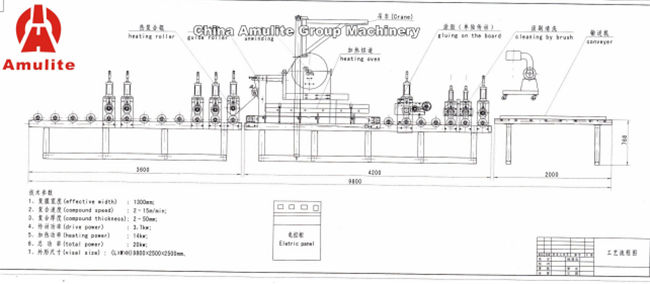

1.AM1300 Type Laminating Machine For Gypsum Boards

(it is used to wrapping PVC film on the surface of gypsum boards)

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 14kw |

| driver power | 3.7kw |

| total power | 20kw |

| visual size(L*W*H) | 9800*2500*2500mm |

flow chart of AM1300

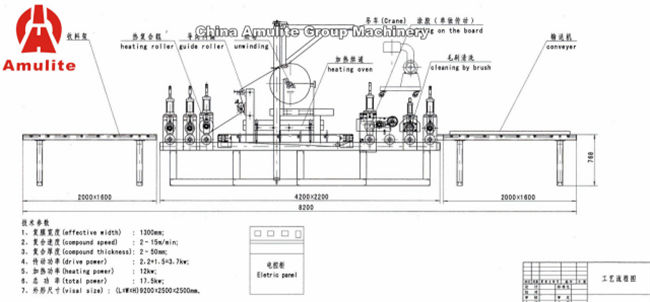

2.AM1300 Type Laminating Machine

(It is used to wrapping aluminum foil on the back of gypsum board.)

Technical parameter of AM1300

| Max. laminating width | 1300mm |

| thickness of boards | 2-50mm |

| laminating speed | 2—15m/min |

| unwinding diameter | Φ400mm, aperture Φ76mm |

| gluing method | roller coating on the boards |

| Glue type | White latex |

| heating power | 12kw |

| driver power | 2.2kw |

| total power | 17.5kw |

| visual size(L*W*H) | 9200*2500*2500mm |

Flow chart of AM1300

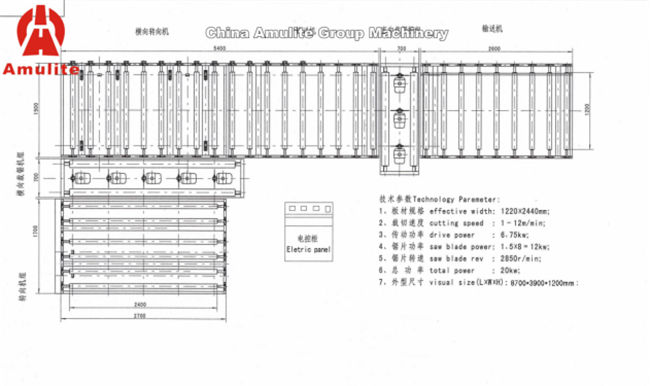

3. AM1220*2440 Type Cutting Machine for Gypsum boards

Technical parameter of cutting machine

| Effective sizes of board | 1220*2440mm |

| Min cutting sizes | 500*500mm |

| cutting speed | 2—12m/min |

| driver power | 6.75kw |

| Saw blade quantity | 8pcs |

| Saw blade power | 1.5kw*8=12kw |

| Saw blade REV. | 2850r/min |

| Power of brush cleaning | 7kw |

| total power | 27kw |

| visual size(L*W*H) | 8700*5300*1200mm |

Flow chart of AM1220*2440

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Europe style for China One-Step Laminated Film PVC Lvt Vinyl Flooring Production Line, We warmly welcome good friends from all walks of life to cooperate with us.

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Europe style for China One-Step Laminated Film PVC Lvt Vinyl Flooring Production Line, We warmly welcome good friends from all walks of life to cooperate with us.

Europe style for China PVC Floor Sheet Machine, Rigid PVC Floor Sheet Production Line, With the development and enlargement of mass clients abroad, now we’ve set up cooperative relationships with many major brands. We’ve got our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We’re provideing high-quality, low-cost products and solutions and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.