Massive Selection for Eps Mortar Foam Board - EPS Sandwich Cement Wall Panels Production Line – Amulite

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Massive Selection for Eps Mortar Foam Board - EPS Sandwich Cement Wall Panels Production Line – Amulite Detail:

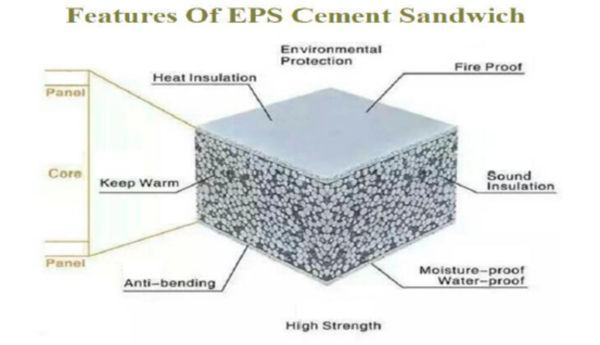

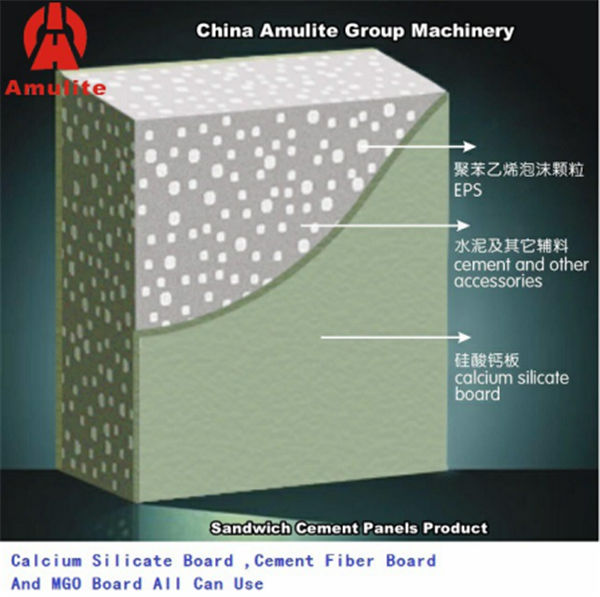

New Lightweight EPS Cement Sandwich Panels Is One New Wall Products, Which Have Good Features Of Energy-Saving ,Environmental Protection, Thermal Insulation, Sound Insulation, Light Weight, Which Make Such Product More Popular All Over The World

Production Process introduction

1.Boiler

Boiler Can Gas Generated, Oil Generated, Electricity Generated, Which Provide Steam For Plant.

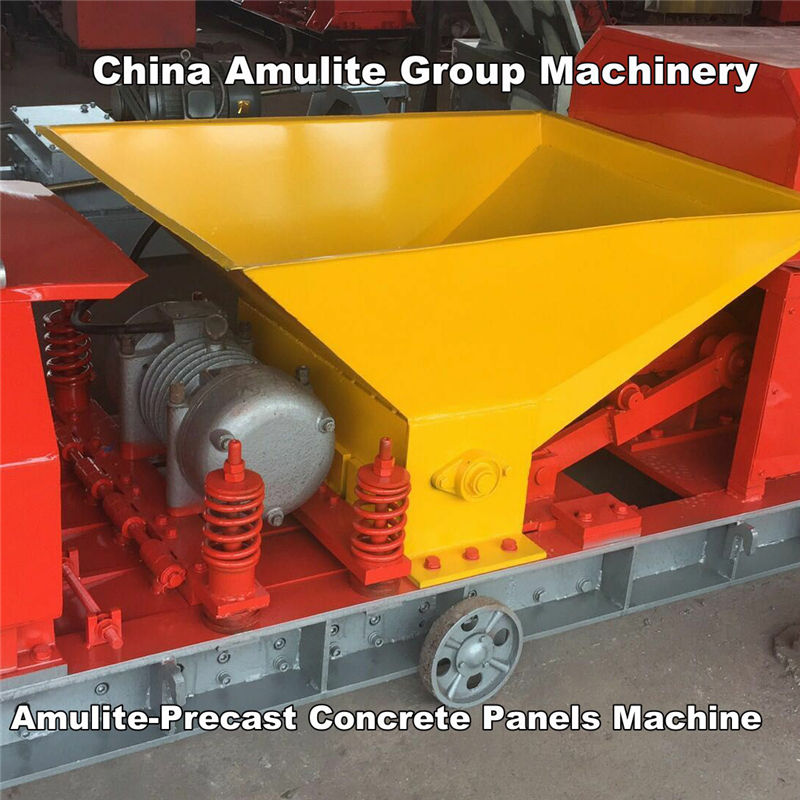

2.Mixer Platform

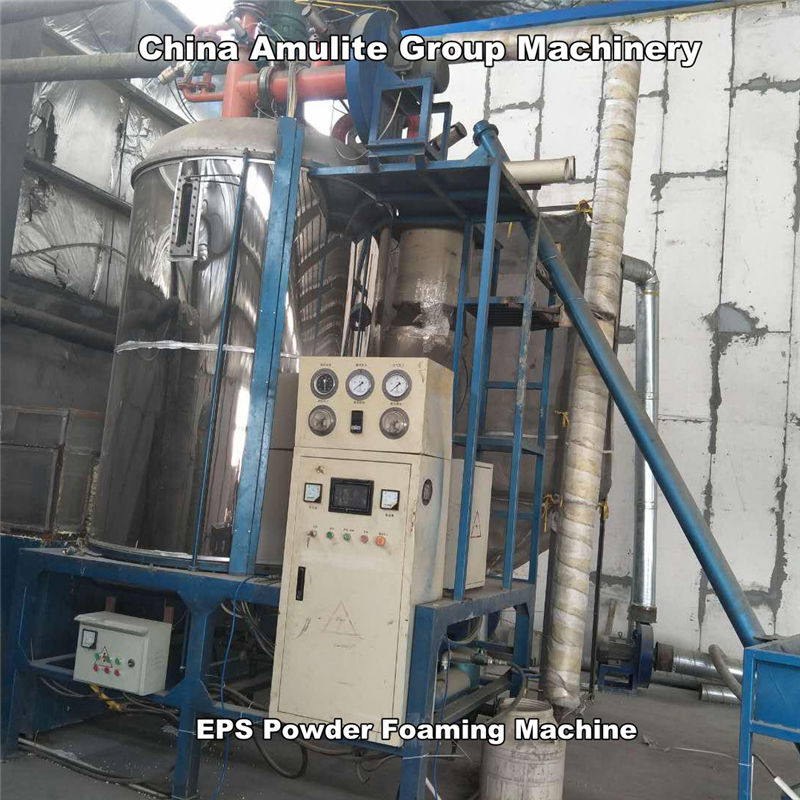

3. EPS Forming Equipment System

Including :EPS Forming Machine, Screw Conveyor, Fluidized Bed, Second Material Tank And Accessories, Mixer Head And Accessories;

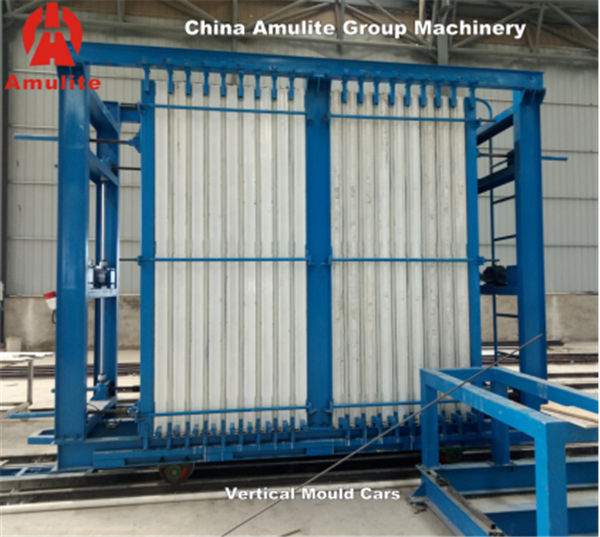

4.Vertical Wall Panel Mould Car

Vertical Panel Mould Car Can Produce 10 Pcs One Times. So The Production Capacity Is Very Higher.

5. Fully Automatically Demould Car

It Is Fully Automatically Demolding The Wall Panel. It Can Demould 5 Sheets One Time And Need About 20 Mins For One Mould Car, Which Improve The Capacity And Save Labor Cost.

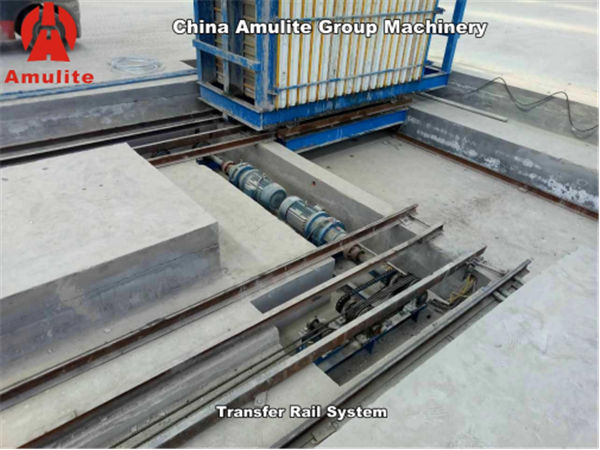

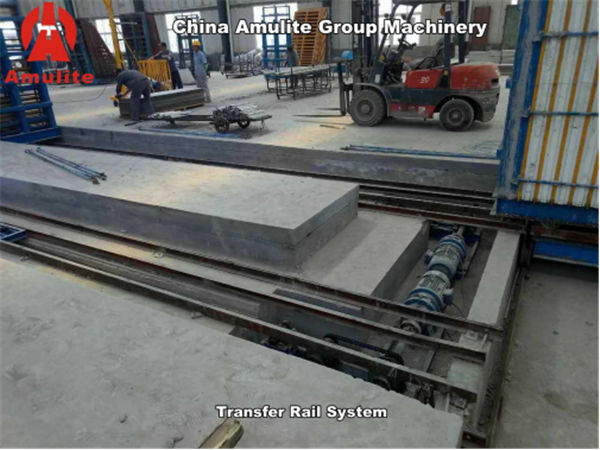

6.Automatic Transfer Cars System

Including :Traction System, Which Make Mould Cars To Move Freely Between Front And Back ; Ferry Cars System, Which Make Mould Cars Can Transfer Between Different Rails;

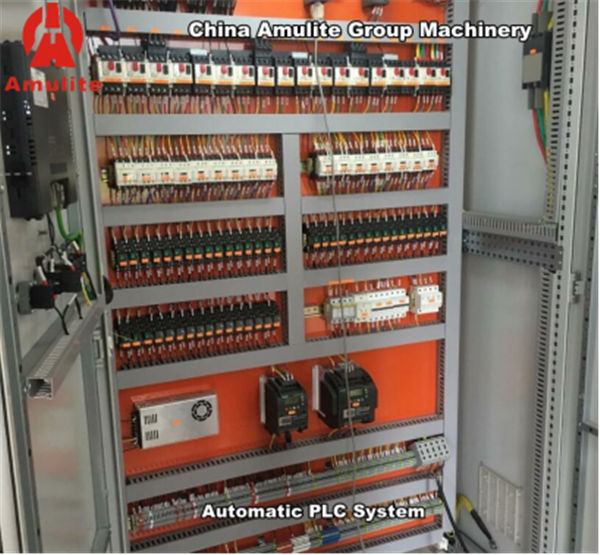

7.P LC Control Cabinet

For The Control System, We Use PLC SIMENS System With Higher Quality.

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Massive Selection for Eps Mortar Foam Board - EPS Sandwich Cement Wall Panels Production Line – Amulite, The product will supply to all over the world, such as: Lithuania, Israel, Mauritius, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.